The Stack: Practical Sculpture in Concrete

PRACTICAL SCULPTURE IN CONCRETE THE STACK TEXT BY PETER ENSENBERGER PHOTOGRAPHS BY DEBS METZONG

One morning, as my carpool companion and I rode the surge of traffic along the Black Canyon Freeway on our way to Arizona Highways' offices, we were struck by the irony of our situation. We were crawling along the hot pavement of Phoenix's main artery, slowed almost to a standstill by work on an interchange whose purpose is to speed our trip. Bumperto-bumper automobiles choked the highway, and we had plenty of time to observe the construction activity taking place on both sides of the road. It's called The Stack: four levels, eight ramps, 347 supporting piers, all tying together two major freeways like a mammoth bow of concrete ribbon. The huge construction project was divided into two phases. The Tanner Companies' $62.8 million bid for Phase I gave them the largest contract for highway

THE STACK

construction in Arizona's history. It called for erecting The Stack while rebuilding the north-south Black Canyon (Interstate Route 17) so it would mesh with east-west Interstate 10.

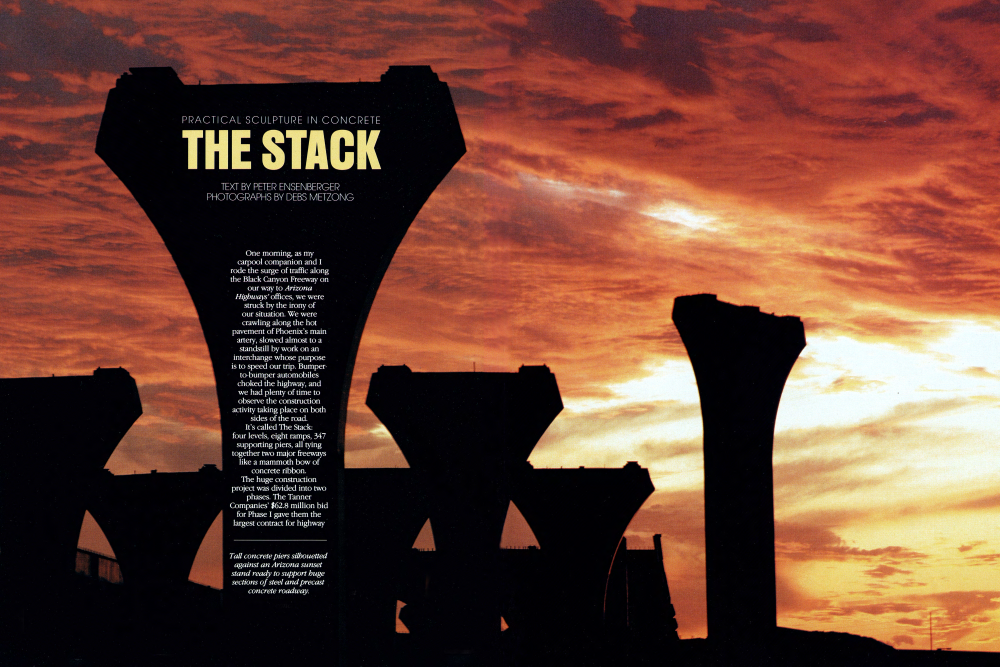

In the summer of 1986, earthmovers began displacing hundreds of thousands of cubic yards of soil. Then, like giant mushrooms, concrete piers in various sizes and shapes began to spring up, seemingly almost overnight.

I remember seeing the piers silhouetted against a vermilion sunset one evening during our rush-hour drive home. Viewing their careful placement, I realized that this massive project demanded an incredible degree of precision. Unless each pier was positioned at exactly the right angle and height, the steel or precast concrete sections of soaring ramps would not align. Inasmuch as The Stack's uppermost level towers 85 feet above I-17, a slight miscalculation could mean catastrophe.

Thereafter my companion and I began to take more interest in the builders' progress, and the inconvenience of traffic tie-ups seemed to matter less. We observed the gradual changes identifiable at the end of each day. Occasional detours gave us new vantage points from which to inspect the project. At the height of construction, 350 workers swarmed over the interchange site.

Weeks and months passed as we watched the great complex emerge: 10 million pounds of steel reinforcing rods, 76,000 cubic yards of concrete, and 21 million pounds of structural steel went into place. By the time Phase I was completed, it was August of 1988.

Phase II was under way before Phase I was finished. Kasler Corporation of San Bernardino, California, won the $30.9 million contract to complete the Papago Freeway (I10.) overpass and the four ramps required to finish the interchange. In March, 1988, Kasler began erecting the last 97 piers. If work continues on schedule, the job will be finished in May.

When the project ends and the interchange opens in all directions, I think my friend and I will miss each evening's check of the day's results. Those involved in building this impressive monument can rightly look on their achievements with pride. But for me as for any kid who ever played with an Erector set-the greatest fun was in the building.

Sweeping curves of The Stack's elevated ramps (OPPOSITE PAGE, CLOCKWISE FROM BOTTOM) give the interchange an architectural appeal. Commuters accept daily traffic tie-ups in the knowledge that the construction project will eventually shorten their driving time. Bird's-eye view of The Stack as it nears its scheduled completion in May. (ABOVE) A massive grid of steel beams frames an ironworker 85 feet above the ground. (LEFT) The form for one of 347 concrete piers is assembled by a construction crew. The concrete will then be pumped into the form from the top.

Already a member? Login ».