Touring Arizona

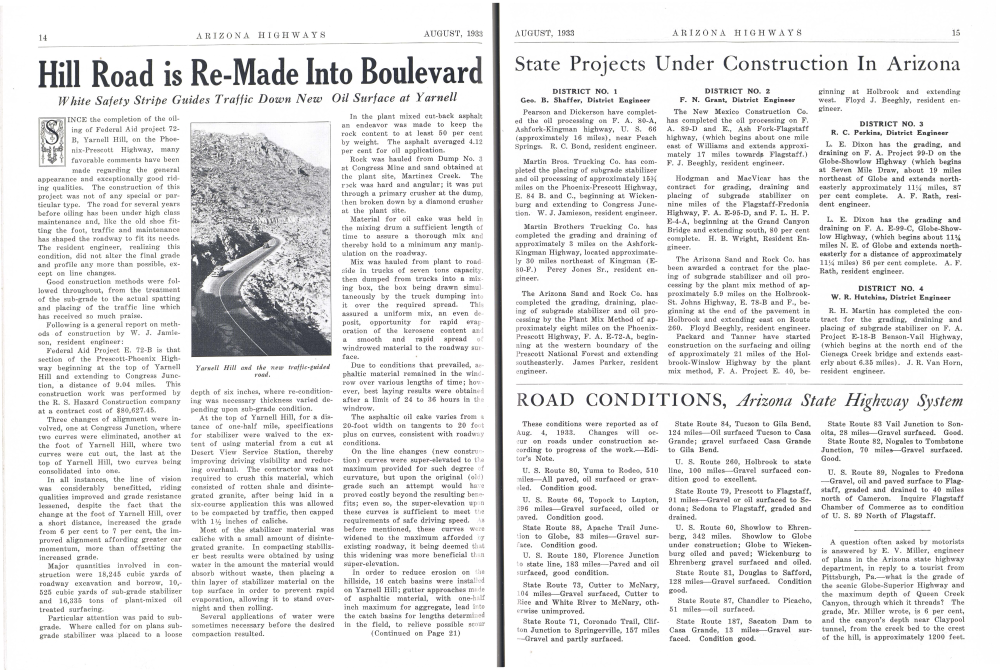

14 ARIZONA HIGHWAYS AUGUST, 1933 Hill Road is Re-Made Into Boulevard White Safety Stripe Guides Traffic Down New Oil Surface at Yarnell

SINCE the completion of the oil-ing of Federal Aid project 72-B, Yarnell Hill, on the Phoe-nix-Prescott Highway, many favorable comments have been made regarding the general appearance and exceptionally good rid-ing qualities. The construction of this project was not of any special or par-ticular type. The road for several years before oiling has been under high class maintenance and, like the old shoe fit-ting the foot, traffic and maintenance has shaped the roadway to fit its needs. The resident engineer, realizing this condition, did not alter the final grade and profile any more than possible, ex-cept on line changes. Good construction methods were fol-lowed throughout, from the treatment of the sub-grade to the actual spatting and placing of the traffic line which has received so much praise.

Following is a general report on meth-ods of construction by W. J. Jamie-son, resident engineer: Federal Aid Project E. 72-B is that section of the Prescott-Phoenix High-way beginning at the top of Yarnell Hill and extending to Congress Junc-tion, a distance of 9.04 miles. This construction work was performed by the R. S. Hazard Construction company at a contract cost of $80,627.45.

Three changes of alignment were in-volved, one at Congress Junction, where two curves were eliminated, another at the foot of Yarnell Hill, where two curves were cut out, the last at the top of Yarnell Hill, two curves being consolidated into one.

In all instances, the line of vision was considerably benefitted, riding qualities improved and grade resistance lessened, despite the fact that the change at the foot of Yarnell Hill, over a short distance, increased the grade from 6 per cent to 7 per cent, the im-proved alignment affording greater car momentum, more than offsetting the increased grade.

Major quantities involved in construction were 18,245 cubic yards of roadway excavation and borrow, 10,-525 cubic yards of sub-grade stabilizer and 16,335 tons of plant-mixed oil treated surfacing.

Particular attention was paid to sub-grade. Where called for on plans sub-grade stabilizer was placed to a loose depth of six inches, where re-conditioning was necessary thickness varied depending upon sub-grade condition.

At the top of Yarnell Hill, for a dis-tance of one-half mile, specifications for stabilizer were waived to the ex-tent of using material from a cut at Desert View Service Station, thereby improving driving visibility and reduc-ing overhaul. The contractor was not required to crush this material, which consisted of rotten shale and disinte-grated granite, after being laid in a six-course application this was allowed to be compacted by traffic, then capped with 1½ inches of caliche.

Most of the stabilizer material was caliche with a small amount of disintegrated granite. In compacting stabilizer best results were obtained by using water in the amount the material would absorb without waste, then placing a thin layer of stabilizer material on the top surface in order to prevent rapid evaporation, allowing it to stand over-night and then rolling. Several applications of water were sometimes necessary before the desired compaction resulted.

In the plant mixed cut-back asphalt an endeavor was made to keep the rock content to at least 50 per cent by weight. The asphalt averaged 4.12 per cent for oil application.

Rock was hauled from Dump No. 3 at Congress Mine and sand obtained at the plant site, Martinez Creek. The rock was hard and angular; it was put through a primary crusher at the dump, then broken down by a diamond crusher at the plant site.

Material for oil cake was held in the mixing drum a sufficient length of time to assure a thorough mix and thereby hold to a minimum any manipulation on the roadway.

Mix was hauled from plant to road-side in trucks of seven tons capacity, then dumped from trucks into a mixing box, the box being drawn simultaneously by the truck dumping into it over the required spread. This assured a uniform mix, an even deposit, opportunity for rapid evaporation of the kerosene content and a smooth and rapid spread of windrowed material to the roadway surface.

Due to conditions that prevailed, asphaltic material remained in the wind-row over various lengths of time; how-ever, best laying results were obtained after a limit of 24 to 36 hours in the windrow.

The asphaltic oil cake varies from a 20-foot width on tangents to 20 foot plus on curves, consistent with roadway conditions.

On the line changes (new construction) curves were super-elevated to the maximum provided for such degree of curvature, but upon the original (old) grade such an attempt would have proved costly beyond the resulting benefits; even so, the super-elevation upon these curves is sufficient to meet the requirements of safe driving speed. As before mentioned, these curves were widened to the maximum afforded by existing roadway, it being deemed that this widening was more beneficial than super-elevation.

In order to reduce erosion on the hillside, 16 catch basins were installed on Yarnell Hill; gutter approaches made of asphaltic material, with one-half inch maximum for aggregate, lead into the catch basins for lengths determined in the field, to relieve possible scour (Continued on Page 21)

Already a member? Login ».